Product

Automated equipment

Automated equipment

Hi-Speed Laser / Press Notching Machine

| specification | 1. Cathode line speed 1000mm/sec: Laser Type 2. Differentiation of fume removal devices 3. Vision processing speed responsiveness |

|---|

Automated equipment

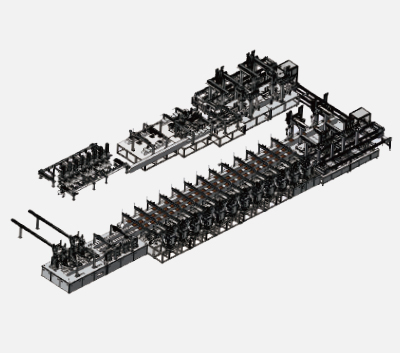

Reel Cut Stacking Machine

1. Production Scope

| Material | Width(mm) | Max. Outer diameter of material |

|---|---|---|

| (+)electrode | 300 ~ 610 | ∮800 |

| (+)electrode | 300 ~ 610 | ∮800 |

| Separator | 280 ~ 630 | ∮400 |

| End tape | 10 ~ 30 | ∮200 |

2. Equipment Specification

| Item | Specification |

|---|---|

| Tac time(sec) | 0.6 |

| Pulling time(sec) | 7 |

| Yield | |

| Operation ratio | ≥98% |

| Yield rate | ≥95% |

| Noise | ≤80db |

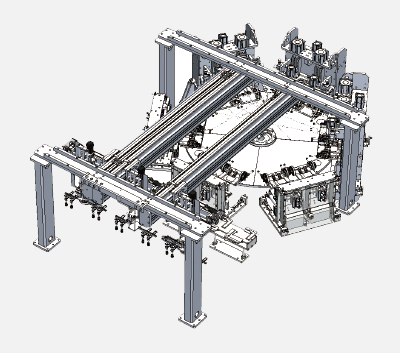

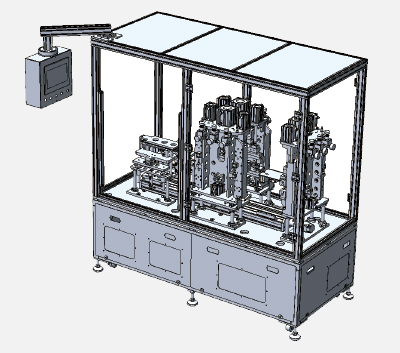

Automated equipment

Magazine Stacking Machine

1. Production Scope

| Item | Time(sec) | PPM | 비고 |

|---|---|---|---|

| Stacking time(1sheet) | 0.6/sec | ||

| pulling time | 10 |

2. Equipment Specification

| NO | X(width) | Y(length) | PPM | Remark |

|---|---|---|---|---|

| Max | 120 | 600 | 18 | Tab(not including) |

| Min | 70 | 500 | 1 |

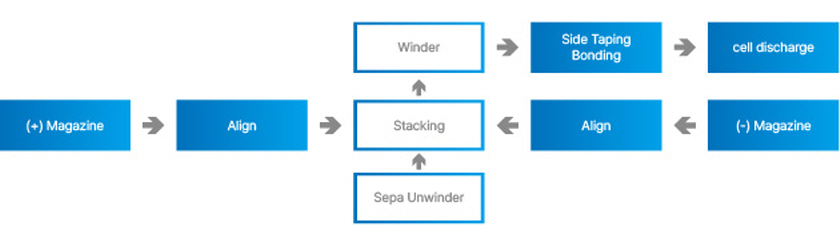

3. Process

Automated equipment

Slitter

| Equipment size | 2400 × 1000 × 2000 |

|---|---|

| Purpose of use | Electrode slitting |

Automated equipment

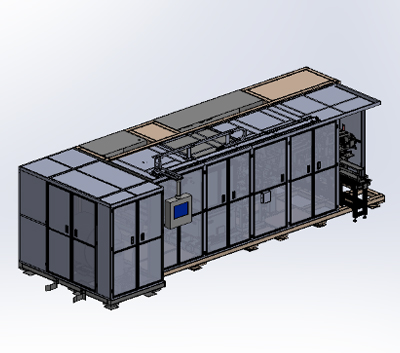

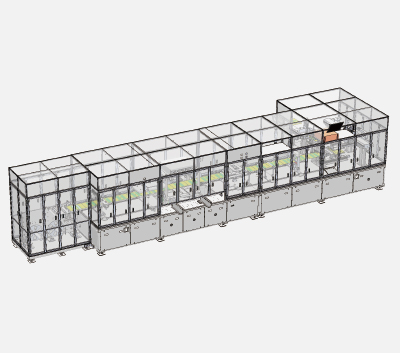

Medium/Large size Degas line

| Equipment size | 24000 × 12000 × 2400 |

|---|---|

| Purpose of use | Electric vehicle, ESS battery production (Degas process) |

Automated equipment

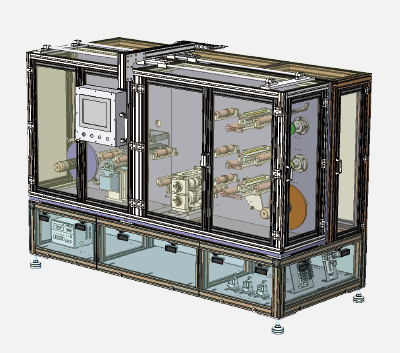

Small size degas line

| Equipment size | 16000 × 4000 × 2200 |

|---|---|

| Purpose of use | Mobile, portable device Battery production (Degas process) |

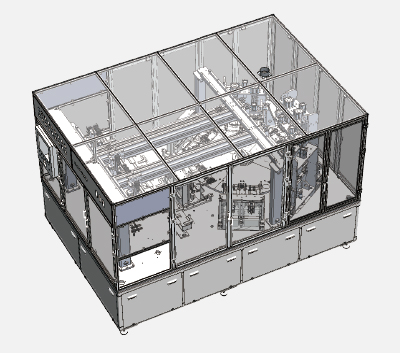

Automated equipment

Medium·large forming line

| Equipment size | 10000 × 4000 × 2200 |

|---|---|

| Purpose of use | Medium and large battery production |

Automated equipment

Small forming line

| Equipment size | 4000 × 1500 × 2000 |

|---|---|

| Purpose of use | Small battery production |

Automated equipment

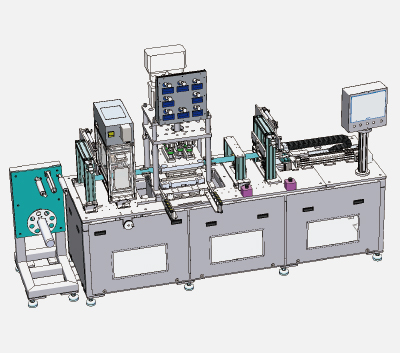

Sealing M/C

| Equipment size | 1800 × 800 × 2000 |

|---|---|

| Purpose of use | Pouch sealing |