Machine parts

Knife unit

- Equipment for slitting rolls of cathode and anode materials for secondary batteries

- A very sophisticated facility that requires a slitting speed of 150m/min and a burr within 10㎛ during unwinding and rewinding.

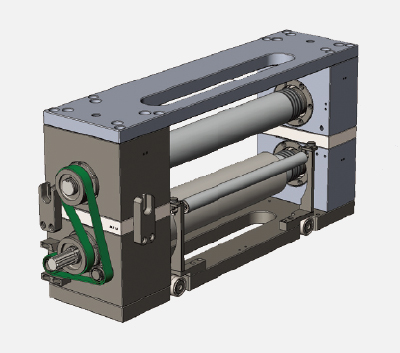

Friction shaft

- Equipment to wind electrode roll in the secondary battery slitting process

- By attaching a bearing housing with a ball roller inserted between the existing friction shafts, it is easy to slide the heavy electrode core, and it is possible to shorten the attaching and detaching time of the operator.

- Precision machining and assembly technology is required at 4,000R.P.M, without air leak between each part

Notching press unit

- Equipment to settle and punch molds in the secondary battery notching process

- The mold is seated and fixed and the upper and lower plates move up and down at the same time to improve the punching speed

- Precision equipment capable of maintaining electrode transfer speed 800~1,000mm/sec during mass production

Lami-cutter unit

- Equipment to cut anode and cathode cells in the secondary battery lamination process

- Cartridge type mold cutter

- The upper & lower cutter has a cartridge-integrated type, so it is easy to replace. The replacement time can be shortened to 5 minutes.

- Reduce maintenance cost by minimizing the range of regrinding

- Cutting quality is maintained by Cutter's Clearance, not by Cutter's lateral pressure or cross-cutting method.