Precision metallic mold

Notching mold

- Tab-shaped punching mold on the anode and cathode thin film of secondary battery

- Precision clearance of the punch and die of the cutting part is in units of microns, and precision tolerance is required for design, processing, and assembly.

- Use of ultra-fine powdered carbide to reduce the anti-power generated during die & punch punching and to improve wear resistance

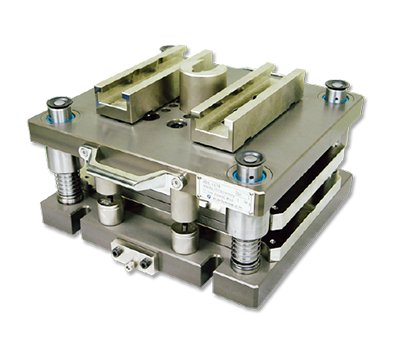

Forming mold

- Mold to draw aluminum pouch of secondary battery in cup shape

- Precision is required to deliver an aluminum pouch with an average thickness of 113㎛ to the punch with a uniform pressure.

- Use of synchronous driven stripper to prevent whitening and wrinkles from occurring during pouch forming

Blanking mold

- Mold for punching the anode and cathode Bi-cell of secondary battery

- Precision mold that can minimize the occurrence of burrs without the removal of active material when punching the coating part of the electrode